NewsNEWS

Featured products

Contact Us

Submersible Pumps and How Do They Work?

2025-06-05Submersible Pumps and How Do They Work? Your Complete Guide

Submersible pumps are engineering marvels designed to operate while completely submerged in the fluid they need to move. Unlike other pumps sitting above ground, submersible pumps work from within the liquid source. This fundamental design offers distinct advantages. But how exactly do these powerful workhorses function? Understanding how submersible pumps work is key to appreciating their efficiency and wide range of applications.

The Core Principle: Pushing, Not Pulling

Most importantly, submersible pumps operate on a push principle. This is different from suction pumps, like jet pumps, that pull water up. Why is this crucial? Physics dictates that suction pumps struggle to lift water more than about 25 feet vertically due to atmospheric pressure limitations.

Submersible pumps eliminate this problem. Because the pump itself sits deep within the water source (a well, borehole, sump, or pond), it doesn’t need to create suction to bring water up. Instead, its job is to push the water powerfully towards the surface. This makes submersible pumps exceptionally effective for deep sources or long vertical lifts. How submersible pumps work inherently solves the depth challenge.

Key Components Inside a Submersible Pump

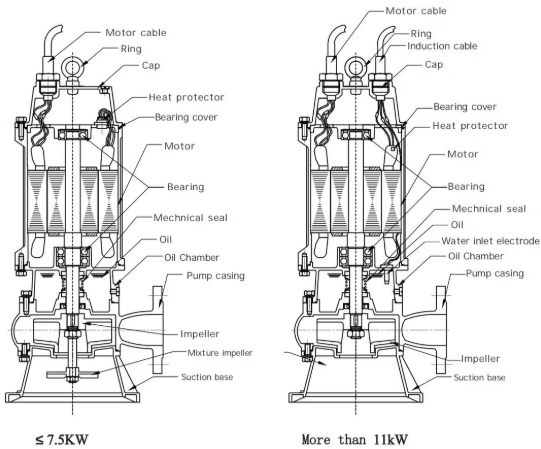

A typical submersible pump consists of several critical parts sealed within a watertight housing:

-

Hermetically Sealed Motor: This is the heart. It’s an electric motor specially sealed to prevent water from entering and causing short circuits. The seal is vital for the pump’s longevity and safety. The motor is usually filled with oil or water for cooling and lubrication.

-

Intake Screen/Sump: Located at the bottom of the pump unit. This screen filters out large debris like sand, stones, or leaves, preventing damage to the internal components.

-

Impellers: These are rotating discs with curved blades. Multiple impellers are usually stacked in series (multi-stage design), especially for deep-well applications. As the motor spins the shaft, the impellers spin rapidly.

-

Diffusers/Volute Casings: Stationary components surrounding the impellers. They capture the water flung outward by the spinning impellers. The diffuser’s shape efficiently converts the high-speed, low-pressure water flow from the impeller into a slower, high-pressure stream ready for discharge.

-

Discharge Outlet: The point where the pressurized water exits the pump. This connects to the pipe or hose that carries the water to its destination (like a pressure tank or surface point).

-

Power Cable: Supplies electricity to the submerged motor. This cable must be robust and waterproof, running all the way from the power source down to the pump.

The Working Process: Step by Step

So, how do submersible pumps work step-by-step? Here’s the sequence:

-

Submersion: The entire pump unit is lowered into the fluid (water, sewage, slurry, etc.) until fully submerged.

-

Power On: Electricity flows through the waterproof cable to the hermetically sealed motor.

-

Motor Spin: The motor starts spinning its central shaft at high speed.

-

Impeller Action: The impellers attached to the shaft spin rapidly. Their curved blades grab the surrounding fluid.

-

Centrifugal Force: Spinning impellers use centrifugal force. This force flings the fluid outward from the center of the impeller towards its outer edges.

-

Pressure Creation: As fluid is flung outward, velocity increases. This high-velocity fluid enters the stationary diffuser or volute casing surrounding the impeller.

-

Velocity to Pressure Conversion: The diffuser/volute casing is specially shaped. It gradually expands. This expansion slows down the fluid’s velocity. Crucially, according to fluid dynamics (Bernoulli’s principle), slowing the velocity increases the fluid’s pressure.

-

Discharge: The now high-pressure fluid is directed towards the pump’s discharge outlet.

-

Piping Transport: The pressurized fluid is forced upward and out through the connected discharge pipe, traveling to the surface or its intended delivery point. In multi-stage submersible pumps, fluid exits one impeller/diffuser stage and enters the next, gaining even more pressure with each stage.

-

Continuous Flow: As long as the motor runs and the pump stays submerged, this process creates a continuous, powerful flow of pressurized fluid.

Submersible Pumps and How Do They Work?

Where Submersible Pumps Excel: Common Applications

Because how submersible pumps work involves direct immersion and pushing action, they are ideal for:

-

Deep Wells & Boreholes: The standard solution for residential and agricultural water supply from deep underground sources. Submersible pumps handle the depth efficiently.

-

Sump Pits: Removing accumulated groundwater from basements to prevent flooding. Submersible sump pumps are the most common type used here.

-

Sewage & Effluent Handling: Specially designed submersible sewage pumps or effluent pumps handle wastewater containing solids, crucial for septic systems and wastewater treatment.

-

Pond & Lake Management: Used for drainage, aeration, or fountain operation. Submersible pumps handle the water directly.

-

Industrial Processes: Moving water, chemicals, or other liquids in manufacturing settings.

-

Dewatering: Removing water from construction sites, mines, or flooded areas.

-

Oil Wells: Specialized high-temperature, high-pressure submersible pumps are used in the oil industry.

Advantages of the Submersible Pump Design

The way submersible pumps work provides significant benefits:

-

Efficiency: No energy is wasted creating suction lift. Pushing fluid is more efficient. Motor cooling by the surrounding fluid also improves efficiency.

-

Quiet Operation: Being submerged muffles motor and vibration noise significantly.

-

Priming Not Required: Since the pump starts submerged, it’s always primed and ready to move fluid immediately.

-

Space Saving: No above-ground pump house or equipment is needed (except the control/pressure system).

-

Reduced Cavitation Risk: Cavitation (damaging vapor bubbles forming) is less likely because the pump is under positive pressure from the surrounding fluid.

-

Good for Deep Sources: As mentioned, the primary solution for deep water extraction.

Important Considerations for Submersible Pumps

-

Motor Seal Integrity: The hermetic seal is critical. If it fails, water enters the motor, causing failure. Quality seals are paramount.

-

Correct Sizing: The pump must be sized correctly for the depth (head pressure), required flow rate (GPM/LPM), and the liquid type (clean water, sewage, abrasive slurry). Using a pump outside its design parameters shortens its life.

-

Power Supply & Control: Requires proper electrical wiring (often deep underground) and usually a control box/pressure switch system.

-

Maintenance Access: While generally reliable, accessing a deep submersible pump for repair or replacement can be more complex and costly than servicing an above-ground pump. Preventative maintenance is key.

Conclusion: Power Where It’s Needed

Submersible pumps offer a powerful, efficient, and often essential solution for moving fluids from significant depths or submerged locations. Understanding how submersible pumps work – their sealed motor spinning impellers to create pressure and push fluid directly from within the source – highlights their unique engineering and advantages. Whether providing water from a deep well, keeping your basement dry, handling wastewater, or managing a pond, submersible pumps are the reliable workhorses operating silently below the surface. Choosing the right type and size of submersible pump ensures optimal performance and longevity for your specific fluid-moving needs.