NewsNEWS

Featured products

Contact Us

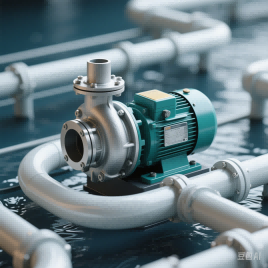

Cavitation in Water Pumps and Causes, Effects, and Prevention

2025-04-181. How Does Pump Cavitation Occur?

Cavitation in Water Pumps and Causes, Effects, and Prevention

To understand cavitation, let’s start with a daily example: Under normal atmospheric pressure (1 atm), water boils at 100°C, producing bubbles. However, at high altitudes where air pressure is lower, water boils below 100°C. If the pressure drops to 0.024 atm or lower, even room-temperature water (20°C) will boil and release bubbles. This shows that liquid vaporization depends on both temperature and pressure.

The critical pressure at which a liquid vaporizes at a specific temperature is called the vaporization pressure (or saturated vapor pressure), denoted as p.

How Centrifugal Pumps Work

Centrifugal pumps lift liquid by creating a vacuum at the inlet. When the impeller rotates, it generates centrifugal force, lowering the inlet pressure below atmospheric pressure. This allows liquid from the reservoir (under atmospheric pressure) to flow into the pump.

However, if the pump is installed too high above the liquid level, the inlet pressure must drop even further to maintain suction. If this pressure falls below the liquid’s vaporization pressure at its current temperature, vapor bubbles form—even in cool liquids.

The Cavitation Process

These bubbles travel with the liquid into the impeller channels. As the impeller transfers energy to the liquid, pressure gradually increases. The bubbles then collapse violently, releasing high-pressure shockwaves (a phenomenon called water hammer).

Over time, these repeated impacts fatigue the metal surfaces, causing pitting and erosion—a process known as cavitation damage. Additionally, gases like oxygen in the bubbles accelerate chemical and electrochemical corrosion, worsening the damage.

Effects of Cavitation

Initially, cavitation causes minor performance issues. However, as it progresses:

- Pump efficiency, flow rate, and head (pressure) drop sharply.

- Noise and vibrations increase.

- Severe cases lead to flow interruption and pump failure.

Cavitation testing often monitors these performance changes to detect early signs.

2. Understanding Net Positive Suction Head (NPSH)

NPSH (Net Positive Suction Head) is the minimum pressure required at the pump inlet to prevent cavitation under specific operating conditions (flow rate, speed, and liquid type). It ensures the pump operates without bubble formation.

Key Signs of Cavitation

- Visible bubble formation.

- Increased noise and vibrations.

- Sudden drops in head or efficiency.

- Pitting or erosion on impeller surfaces.

Why NPSH Matters

Pumps rely on maintaining sufficient NPSH to avoid cavitation. Engineers must calculate and ensure the required NPSH for safe operation, especially in high-lift or high-temperature applications.

By addressing cavitation risks early, pump longevity and efficiency can be preserved.