NewsNEWS

Featured products

Contact Us

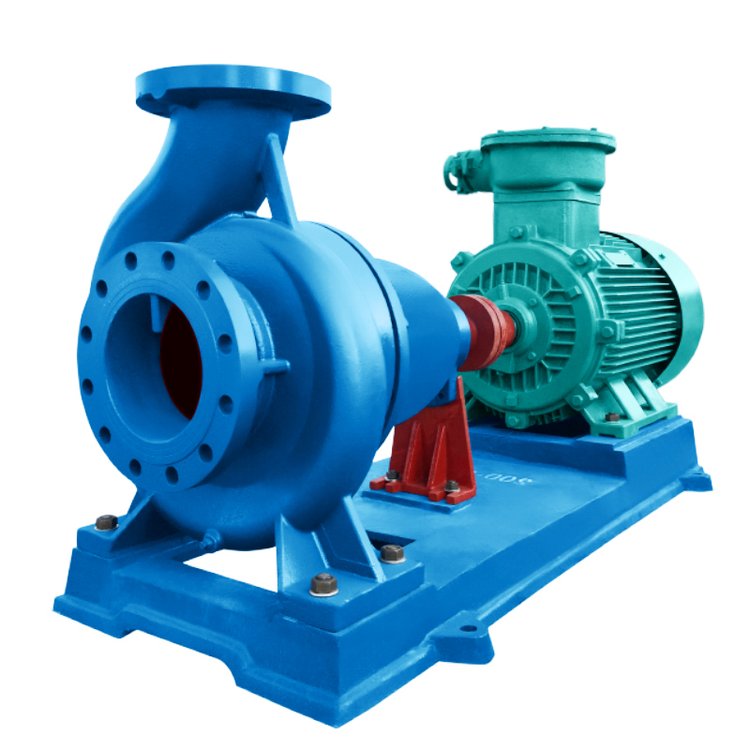

Pipeline Centrifugal Pumps for Peak Performance & Reliability

2025-05-30Installation, Start-up & Operation: Mastering Your Pipeline Centrifugal Pumps for Peak Performance & Reliability

Pipeline centrifugal pumps are the indispensable workhorses of countless industries. From moving water and oil to transporting chemicals and slurries, their efficient operation is paramount. Proper installation, start-up, and operation methods for pipeline centrifugal pumps are not mere suggestions – they are the bedrock of reliability, efficiency, safety, and longevity. Neglecting these critical procedures leads to costly downtime, premature failures, and potential hazards. This comprehensive guide dives deep into each stage, providing the essential knowledge to ensure your pipeline centrifugal pumps perform flawlessly for years to come.

Why Getting It Right Matters: The High Cost of Cutting Corners

Ignoring best practices in pipeline centrifugal pump installation, start-up, and operation has severe consequences:

-

Catastrophic Failure: Misalignment, dry running, or cavitation can destroy impellers, bearings, and seals in minutes.

-

Chronic Downtime: Repeated breakdowns disrupt production schedules and inflate maintenance budgets.

-

Skyrocketing Energy Bills: Pumps operating far from their Best Efficiency Point (BEP) waste significant power.

-

Safety Incidents: Improper handling of fluids under pressure, hazardous materials, or hot surfaces poses serious risks.

-

Shortened Lifespan: Premature wear due to vibration, contamination, or overload drastically cuts pump life.

Investing time and resources in mastering the installation, start-up, and operation methods for pipeline centrifugal pumps pays massive dividends in reduced costs, enhanced safety, and uninterrupted operation.

Phase 1: Foundational Precision – Pipeline Centrifugal Pump Installation

The journey to reliable pumping begins long before the first start button is pressed. Correct installation sets the stage for everything that follows. Here’s how to ensure your pipeline centrifugal pumps are mounted for success:

-

Site Preparation is Paramount:

-

Ensure the foundation is level, rigid, and capable of supporting the pump’s weight plus dynamic loads. Use grouting under the baseplate as per manufacturer specs.

-

Verify adequate space exists for future maintenance access – around, above, and below the pump and motor. Think seal replacement, bearing access, coupling access.

-

Provide proper lighting and ventilation. Ensure lifting points or equipment are available for safe handling.

-

-

Rigorous Receiving & Handling:

-

Inspect the pump and all components immediately upon arrival for shipping damage. Check crates before signing receipts.

-

Use only designated lifting points. Never lift by the shaft or piping connections! Use slings or spreader bars correctly.

-

Keep protective covers on flanges and openings until ready for connection to prevent contamination.

-

-

Precision Alignment: Non-Negotiable!

-

Roughly position the pump and motor on the baseplate. Ensure piping strain won’t pull the pump out of alignment later.

-

Perform final precision alignment (laser alignment is highly recommended) after the pump is fully connected to piping and the baseplate is grouted/cured. Check alignment cold and hot (if possible).

-

Correct angular and parallel misalignment to within manufacturer tolerances (typically < 0.002″ for couplings). Misalignment is a primary killer of bearings and seals.

-

-

Piping Connections: Minimize Strain, Maximize Flow:

-

SUCTION PIPING IS CRITICAL: Use straight pipe runs (min. 5-10 pipe diameters) before the pump inlet. Avoid elbows close to the suction flange. Ensure piping slopes up towards the pump to prevent air pockets. Use eccentric reducers (flat on top) to prevent air entrapment. Support piping independently near the pump flange to prevent strain.

-

Discharge piping should also be independently supported. Include isolation valves and a check valve downstream of the pump to prevent reverse rotation.

-

Use gaskets suitable for the fluid and pressure. Tighten flange bolts evenly and progressively in a star pattern to avoid distortion.

-

-

Ancillaries & Utilities:

-

Connect seal flush lines (for mechanical seals), cooling lines (if required), and vent lines per the pump P&ID and manufacturer instructions. Ensure proper flow and pressure.

-

Verify electrical connections (motor voltage, phase, rotation) match supply before energizing. Ensure proper grounding.

-

Install instrumentation: pressure gauges on suction and discharge (essential!), temperature sensors (bearings, seal chamber), vibration probes (if equipped). Ensure they are calibrated and functional.

-

Phase 2: The Moment of Truth – Pipeline Centrifugal Pump Start-Up Procedure

A meticulous start-up process is vital for a smooth transition into operation. Never rush this stage! Follow these start-up methods for pipeline centrifugal pumps:

-

Pre-Start Checklist: Your Safety Net

-

Lubrication: Confirm correct oil level/grease quantity and type in bearings. Verify oil rings turn freely (if applicable).

-

Rotation: Bump the motor momentarily (“jog”) to confirm correct shaft rotation direction (should match arrow on pump casing). Reverse motor phases if incorrect.

-

Vents: Open suction and casing vent valves fully. Vent until a solid stream of liquid appears, indicating all air is purged. Close vents securely. Air is the enemy!

-

Seals: Ensure mechanical seals are properly lubricated/flushed per instructions. Check packing gland adjustment (if applicable) – slight leakage is normal initially for packing.

-

Valves: Confirm suction valve is fully OPEN. Discharge valve should be partially or fully CLOSED (consult manual – often started against closed valve for short periods).

-

Guards: Ensure all coupling and rotating equipment guards are securely in place.

-

Clearance: Double-check the area is clear of personnel and tools.

-

-

Initial Start Sequence:

-

Start the motor with the discharge valve throttled (if required by pump type/size).

-

Monitor motor starting current (amperage) – it should drop to normal running levels quickly.

-

Listen intently for unusual noises: grinding, knocking, excessive vibration, squealing. Be prepared to shut down immediately if detected.

-

Observe discharge pressure build-up. Ensure suction pressure remains adequate and stable (above NPSH required).

-

-

Gradual Opening & Monitoring:

-

Slowly open the discharge valve to the desired operating point. Do this gradually to avoid overloading the motor or causing cavitation.

-

Continuously monitor:

-

Amperage: Should be within motor nameplate rating, ideally near full load for efficiency but not exceeding it.

-

Pressures: Suction pressure (must stay above pump NPSHr), Discharge pressure.

-

Vibration: Use hand-held meter if permanent probes not installed. Should be low and smooth (refer to ISO standards or pump specs).

-

Temperature: Bearing housings (should stabilize well below alarm limits), seal flush outlet temperature.

-

Noise: Listen for changes indicating cavitation (sounds like gravel) or other issues.

-

Leakage: Check mechanical seal or packing for acceptable leakage rates. Adjust packing gently only if necessary and while running, following manufacturer guidelines.

-

-

Verify flow rate (if flowmeter installed) matches system requirements and pump curve.

-

-

Reaching Steady State:

-

Once the discharge valve is fully open (or at the desired setting) and all parameters are stable within normal ranges, the pump is considered operational.

-

Record all baseline readings (pressure, amps, vibration, temp, flow) for future reference and troubleshooting. These “healthy” benchmarks are invaluable.

-

Phase 3: The Long Haul – Optimal Pipeline Centrifugal Pump Operation Methods

Sustained performance and reliability depend on vigilant operation. Implement these operation methods for pipeline centrifugal pumps:

-

Operate Near the BEP (Best Efficiency Point):

-

Centrifugal pumps operate most efficiently and with minimal damaging forces (radial thrust, vibration) near their BEP.

-

Consult the pump curve. Strive to operate within 70-120% of the BEP flow rate whenever possible. Avoid prolonged operation far left (low flow) or far right (high flow) on the curve.

-

-

Guard Against Cavitation: The Silent Killer:

-

Cavitation occurs when suction pressure drops too low, causing vapor bubbles to form and violently collapse inside the pump. It sounds like gravel, causes pitting on impellers/vanes, severe vibration, and rapid performance loss.

-

NPSH Available (NPSHa) MUST exceed NPSH Required (NPSHr) by a safety margin (often 1-2 meters or per manufacturer). Monitor suction pressure closely!

-

Causes of low NPSHa: Clogged suction strainer, high fluid temperature, low source level, excessive friction loss in suction piping, high elevation. Address these immediately!

-

-

Routine Monitoring & Data Logging:

-

Daily/Shift Checks:

-

Visual inspection for leaks (seal, gaskets, drains).

-

Listen for abnormal noises (bearing rumble, cavitation roar, rubbing).

-

Feel bearing housings for excessive heat (use back of hand cautiously).

-

Check oil level/condition (sight glass, level plug). Look for cloudiness (water) or discoloration.

-

Record key operating parameters: Suction Pressure, Discharge Pressure, Motor Amps, Flow Rate (if available), Vibration (if monitored).

-

-

Vibration Analysis: Regular monitoring (hand-held or online) is one of the best predictive maintenance tools for pipeline centrifugal pumps. Trend data to spot developing bearing, imbalance, or misalignment issues early.

-

Performance Trending: Compare current pressure/flow/amp readings to baseline and pump curve. Gradual changes indicate wear (e.g., ring wear, impeller erosion).

-

-

Essential Operational Practices:

-

Avoid Dry Running: Never operate a centrifugal pump without liquid inside! Even brief dry running destroys mechanical seals and bearings. Ensure suction source is adequate. Use run-dry protection if risk exists.

-

Minimize Starts/Stops: Frequent cycling causes thermal stress and accelerates wear. Use VFDs for flow control instead of starting/stopping if possible.

-

Throttle on Discharge, Not Suction: Closing the suction valve drastically increases the risk of cavitation. Always throttle flow using the discharge valve.

-

Manage Viscosity & Temperature: Centrifugal pump performance is highly sensitive to fluid viscosity and temperature. Refer to correction factors on pump curves. Ensure fluid properties match design conditions.

-

Prevent Deadheading: Avoid operating against a closed discharge valve for extended periods. This causes fluid recirculation within the pump, leading to overheating, cavitation, and potential damage. Bypass loops or minimum flow orifices/valves are essential for this scenario.

-

Shutdown Procedures: Graceful Exit

Even shutdown requires care to prevent issues like water hammer or thermal shock:

-

Slowly close the discharge valve (if system requires it).

-

Stop the motor.

-

Do not immediately close the suction valve unless isolating for maintenance.

-

For hot pumps or those handling viscous/crystallizing fluids, consider a slow cooldown or flush procedure per manufacturer guidelines.

-

Isolate the pump using suction and discharge valves only when necessary for maintenance. Lockout/Tagout (LOTO) rigorously!

Conclusion: Mastery Equals Reliability & Profitability

Mastering the installation, start-up, and operation methods for pipeline centrifugal pumps is not an optional extra – it’s fundamental engineering practice critical to plant efficiency and profitability. By meticulously following the procedures outlined for pipeline centrifugal pump installation, executing a disciplined start-up sequence, and adhering to vigilant operation practices, you unlock the full potential of these vital assets. The result? Dramatically reduced unplanned downtime, minimized maintenance costs, optimized energy consumption, extended equipment lifespan, and a safer working environment. Investing in the correct installation, start-up, and operation of your pipeline centrifugal pumps is an investment in the smooth, profitable, and reliable future of your operations. Treat your pumps right, and they will deliver for years.

FAQ: Pipeline Centrifugal Pump Installation, Start-Up & Operation

-

Q: How critical is alignment really for pipeline centrifugal pumps?

-

A: Extremely critical! Misalignment is a leading cause of premature bearing failure, seal leaks, coupling wear, and excessive vibration. Precision alignment (laser preferred) after piping connection is non-negotiable for reliable operation.

-

-

Q: Why must I vent the pump before starting?

-

A: Centrifugal pumps move liquid, not air. Air trapped in the casing prevents the pump from priming and generating pressure. It can also cause cavitation-like damage and overheating. Always vent thoroughly until only liquid escapes.

-

-

Q: Should I start the pump with the discharge valve open or closed?

-

A: Generally, start with the discharge valve partially or fully closed. This reduces the starting torque load on the motor (lower amps). Consult your specific pump manual, but starting against a closed valve briefly is common practice. Open the valve slowly to operating point immediately after start.

-

-

Q: What does cavitation sound like, and why is it so bad?

-

A: Cavitation often sounds like gravel or marbles rattling inside the pump. It’s catastrophic because the collapsing vapor bubbles create intense micro-jets that erode metal (impeller, casing), cause severe vibration leading to bearing/seal failure, and drastically reduce pump performance and efficiency.

-

-

Q: Why is operating near the BEP important?

-

A: The Best Efficiency Point (BEP) is where the pump runs with the lowest internal recirculation, radial forces, vibration, and highest efficiency. Operating significantly away from BEP (especially at very low flows) causes excessive heat, vibration, and wear, shortening pump life.

-

-

Q: Can I throttle the suction valve to control flow?

-

A: NO! Throttling the suction valve drastically reduces the Net Positive Suction Head Available (NPSHa), significantly increasing the risk of damaging cavitation. Always control flow using the discharge valve or a Variable Frequency Drive (VFD).

-

-

Q: How often should I check my operating pipeline centrifugal pump?

-

A: Perform basic visual and auditory checks (leaks, noise, bearing temp by touch) at least once per shift. Log key operating parameters (suction/discharge pressure, motor amps) daily. Regular vibration monitoring (weekly/monthly) and oil analysis provide deeper insights for predictive maintenance.

-